Key Specifications / Features

Aluminum forging is a process that involves shaping aluminum using compressive forces applied through dies or molds. The process is used to create a wide range of parts and components used in various industries, including aerospace, automotive, construction, and more. Aluminum forgings are valued for their high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity, making them ideal for use in many applications.

Tags

Detail Information

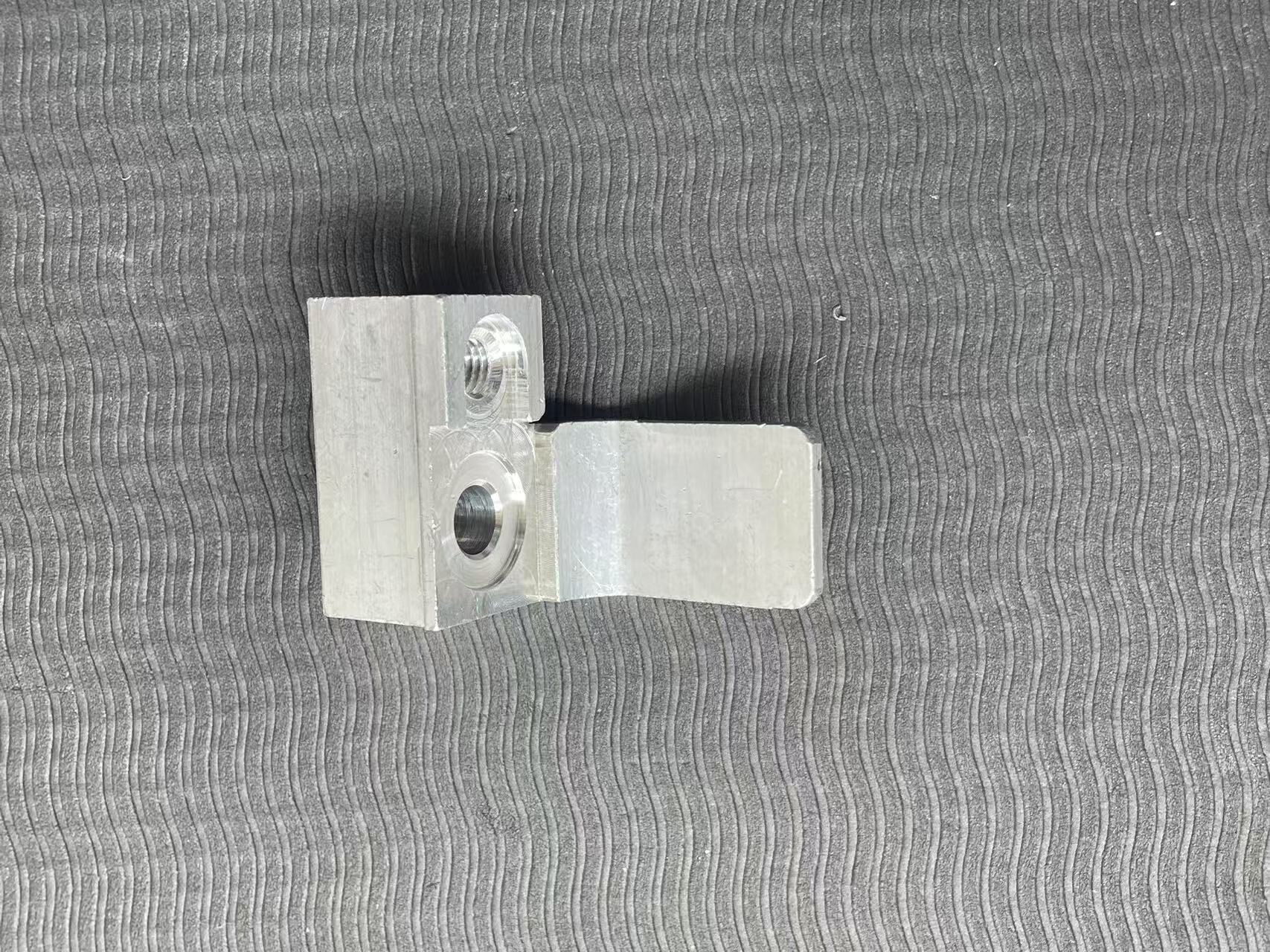

Aluminum link block link block pressure plate valve body,Interface on the air conditioning pipeline,condenser,interface for automobile

Aluminum forging is a process that involves shaping aluminum using compressive forces applied through dies or molds. The process is used to create a wide range of parts and components used in various industries, including aerospace, automotive, construction, and more. Aluminum forgings are valued for their high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity, making them ideal for use in many applications.

CT Forge is a leading provider of aluminum forging services, offering a wide range of capabilities to meet the needs of customers in various industries. With over 20 years of experience in the field, CT Forge has established a reputation for producing high-quality aluminum forgings that meet or exceed customer expectations.