How to Select Forging Materials

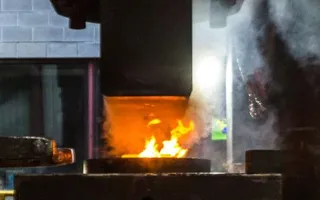

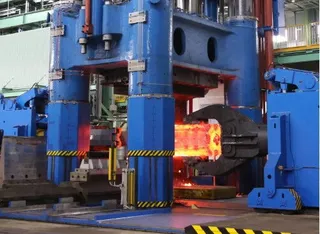

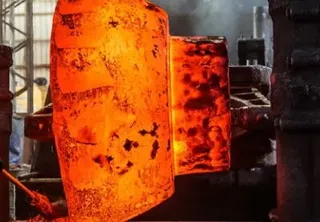

How to Select Forging Materials? The material that is selected for forging process must be one that can achieve the required physical and mechanical properties. Where alloys from several groups meet performance requirements, the most economical alloy, in terms of material and processing costs, should be chosen. See below summary on making a preliminary selection of forging materials: Carbon, microalloyed and alloy steels are low to moderate in cost. The main cost drivers are...