Copper Alloy Forging

Copper Alloy Forging

What Is a Copper Alloy Forging?

A copper forging is produced by subjecting copper, a nonferrous material, to a forming process involving plastic deformation under high pressure and temperatures through hammering and rolling. Due to its ductility and excellent thermal and electrical conductivity properties, copper forgings can be manufactured in various configurations such as rods, bars, wires, sheets, strips, tubing, and more.How Is It Made?

The forging process involves heating the copper alloy to a specific temperature, typically above its recrystallization temperature, to make it more malleable. The heated material is then placed between two dies and subjected to compressive forces, which reshape it into the desired form. This combination of heat and pressure allows for the deformation and consolidation of the copper alloy, resulting in the desired shape and mechanical properties.What Are the Advantages of Copper Alloy Forgings?

● Enhanced Mechanical PropertiesThe forging process refines the grain structure of the copper alloy, resulting in improved mechanical properties such as strength, toughness, and fatigue resistance.

● Design Flexibility

Forging allows for the production of complex shapes with tight tolerances, making it suitable for creating intricate components and parts.

● Improved Surface Finish

Copper alloy forgings generally exhibit better surface finish compared to alternative manufacturing processes, reducing the need for additional finishing operations.

● Cost-effectiveness

Although copper alloys may be more expensive than some other materials, the ability to forge them into near-net shape parts reduces material waste and machining costs.

What Are the Applications of Copper Alloy Forgings?

● Electrical and Electronics IndustryCopper alloy forgings are used in the production of electrical and electronic components such as connectors, switchgear, and relays due to their excellent electrical conductivity and thermal properties.

● Aerospace Industry

In the aerospace sector, copper alloy forgings are used for manufacturing critical components like bearings, landing gear, and engine parts. These forgings offer high strength-to-weight ratio, corrosion resistance, and excellent wear resistance.

● Architecture and Construction Industry

Copper alloy forgings are utilized in the construction industry for various applications such as roofing, cladding, and architectural accents. They provide an aesthetically pleasing appearance and excellent weather resistance.

● Automotive Industry

Copper alloy forgings find application in the automotive industry for manufacturing components such as radiator tanks, engine parts, and bearings due to their high thermal conductivity and excellent wear resistance.

● Defense and Military Applications

Copper alloy forgings are also used in the defense and military sectors for manufacturing components such as ammunition, gun parts, and missile components. The excellent thermal and electrical conductivity properties of copper alloys make them suitable for these applications.

Creator Components offers a complete solution of various copper alloy forgings to meet your needs. For further information on this, please kindly contact us. We are committed to being your trusted source for high quality forgings.

Products List

CR 14 CAF 12

China Customized Copper Machined Forging Part Manufacturer Creator Provides Copper Machined Forging Parts, Annealing Treatment, ISO, RoHS and TUV.

CS 14 CAF 11

China Bronze Machined Forging Wear Part Supplier Creator Offers Bronze Machined Forging Wear Parts, Oiled, Annealing Treatment, SGS, ISO & RoHS.

CR 14 CAF 08

China Customized Bronze Machined Forging Component Provider Creator Manufactures Bronze Machined Forging Components, Electro-plating, Spray Coating.

CR 14 CAF 10

China C12200 Copper Precision Forging Part Supplier Creator Offers Copper Precision Forging Parts for Tools and Hardware Application, Electro-plating.

CR 14 CAF 09

China C22000 Bronze Cold Forging Machined Hardware Supplier Creator Offers Cold Forging Machined Hardwares, 90% Copper, 10% Zinc, ISO, SGS Certified.

CR 14 CAF 07

China Bronze Machined Forging Supplier Creator Provides Bronze Machined Forging Components, Copper Alloy, Powder Coating, OEM Services Available.

CR 14 CAF 06

China Copper Base Alloy Machining Forging Part Manufacturer Creator Supplies Copper Machining Forging Parts, Tools and Hardware Application.

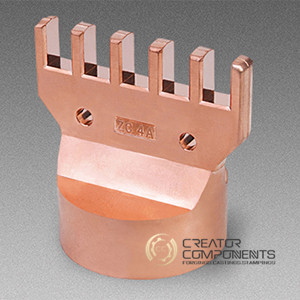

CR 14 CAF 05

China TUV Bronze Machined Forging Component Supplier Creator Provides Bronze Machined Forging Components, Machinery Application, Strict QC System.

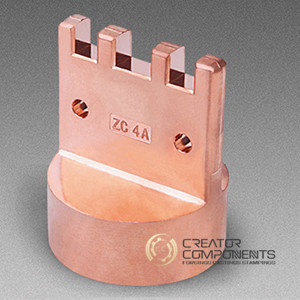

CR 14 CAF 04

China Copper Machined Forging Part Supplier Creator Offers Machined Forging Parts, Copper Alloy, Bronze Alloy, ISO 9001, ISO 14001, TUV Certified.

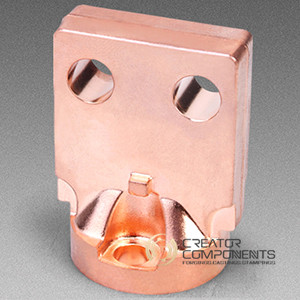

CR 14 CAF 03

China ISO Bronze Machined Forging Part Supplier Creator Offers the best ISO 9001:2008 Certificated

Machined Forging Parts, Machinery Application.

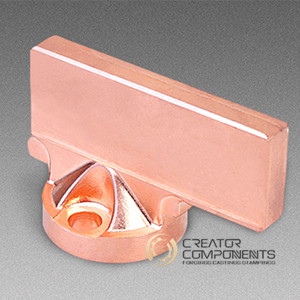

CR 14 CAF 02

China ISO Bronze Alloy Machined Forging Part Provider Creator Offers ISO 9001:2008 Certificated Machined Forging Parts for Machinery Application.

CR 14 CAF 01

China Copper Alloy Machined Forging Part OEM Producer Creator Offers Copper Alloy Forging Parts for Machines, TS 16949, ISO9001: 2000 Certificated.