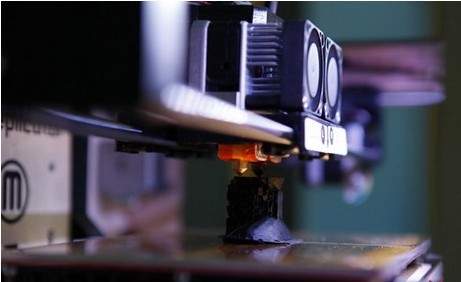

3D Printing Impacting Mold Making

3D printing will overturn the whole manufacturing from origin. The machine will take place of every key step, including moulds, parts, semi-finished products and finished products. Labor force, equipment investment, workers’ skills and line management having closed relationship with conventional manufacturing will be overturned.

Insiders shows that low price promotes 3D printing to be popularized rapidly. Those inexpensive 3D printers still cannot completely take place of injection molding and other traditional manufacturing techniques. But they have ability to print some product prototype and simple toys. However, other experts claim that constant influences of 3D printing still need to be assessed. Without doubt, 3D printing will expand limitation of industrial imagination. In the future, 3D printer will cooperate with milling machine, casting, injection molding and other traditional manufacturing facilities, or even replace them. With yield of 3D printing improving, labor demands will also decrease significantly in the future.

Shapeways, a 3D printing company has already used nylon 12 to print seamless splicing swimsuit directly. It is just only beginning. In the future, any kinds of clothing can be made out through digital technology, without manpower or swing machinery. The largest advantage of 3D printing is that just increasing quantity of machine can improve capacity. Moreover, machine is initial investment. Electric charge is the only considering factor. In the past, manpower should be invested constantly. A conventional injection molding production line needs 5 or 6 workers at least, while a technician can manage dozens of completely automatic manufacturing facilities.

The largest overturn is flexible supply chain. In traditional manufacturing model, when customers come up with production requirements, confirm the production quantity based on market expectation. Then, carry out production. Once the factory is put into operation, no matter supply exceeds demand or demand exceeds supply, the production line cannot be stopped. However, 3D printing can print experimental products at first, then, make decisions according to feedbacks from market.

In the future, 3D printing will lower central role of traditional manufacturing. For example, the advantage of phone industry in Shenzhen is effective supply chain system. Both upstream and downstream can clearly hold market trends. Once products are unsalable or hot sold, the production strategy can be adjusted immediately. While in the period of 3D printing, those do not matter at all. 3D printing can be operated or stopped at any moment. No matter the factory is in Shenzhen or the U.S., sufficient capacity and response rate can be acquired while labor cost and technicians’ technique can be ignored.