Key Technologies for Simulation Software of Stamping

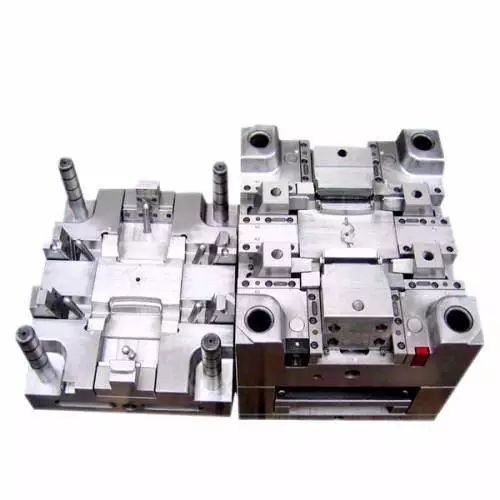

Several key technologies are used for simulation software of stamping 1. Geometric and mechanic model of mold Mold has higher rigidity than sheet. In general, mold is used as rigid body. When referring...