Open Die Forging Services

Open Die Forging Services

What Is Open Die Forging?

What Is Open Die Forging?

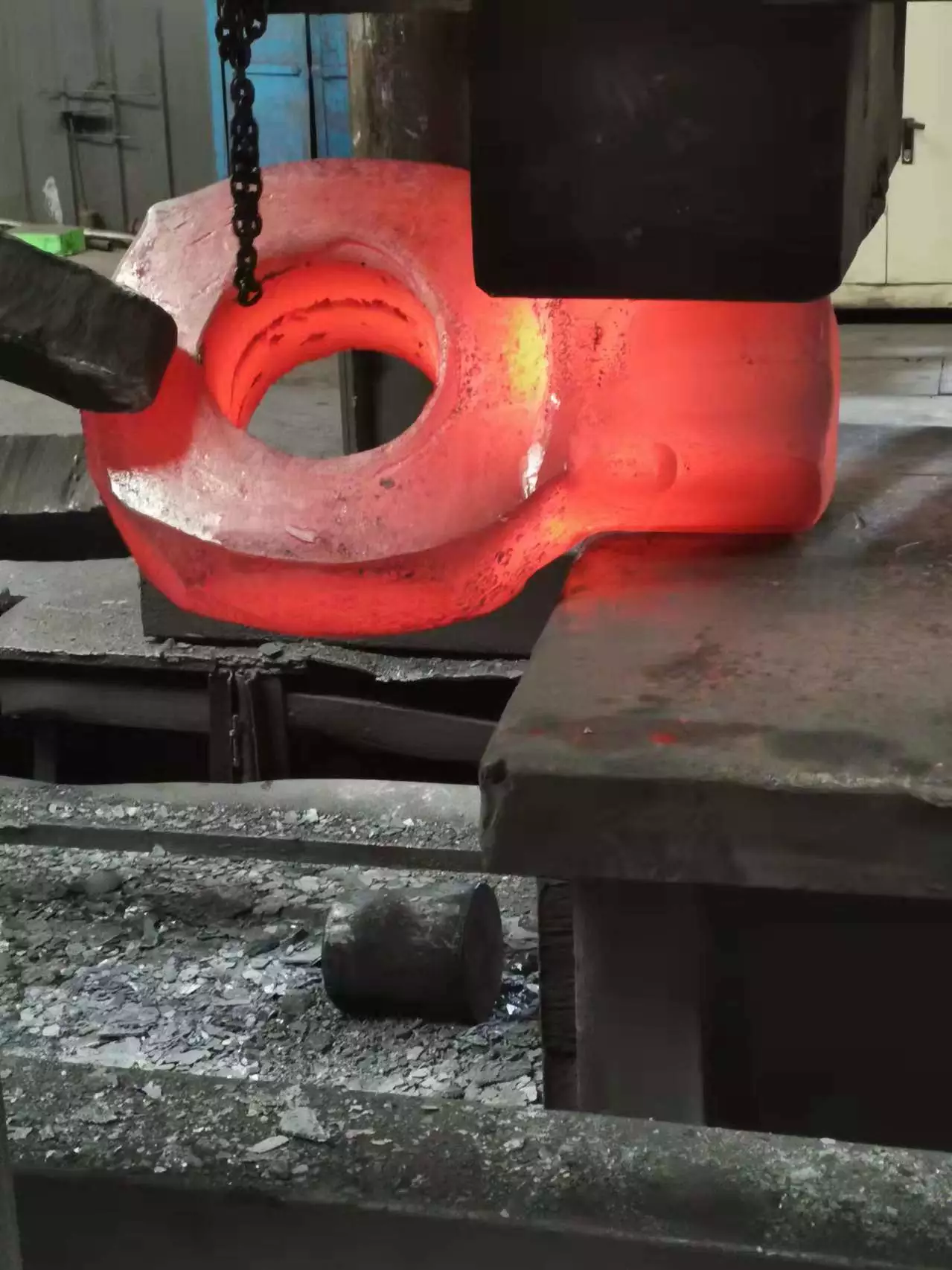

Open die forging, also referred to as smith forging or free forging, is a metalworking technique employed to craft metal into specific shapes by employing compressive force through open dies. In contrast to closed die forging, where the material is entirely enclosed within dies, open die forging entails reshaping the workpiece between two flat or contoured dies that are not completely sealed. This approach offers the unique advantage of accommodating larger products for forging, with capacities reaching up to 150 tons and lengths exceeding 80 feet or more.

The Open Die Forging Features

1. The main feature of open die forging is its relatively simple production equipment, resulting in lower costs. Unlike closed die forging, where the shape is complex and the operation less flexible, open die forging offers a straightforward shape and adaptable operations. Consequently, it plays a pivotal role in heavy machinery equipment due to its simplicity.

2. Another distinguishing feature is the manual control of shape and dimensions in open die forgings. This manual operation leads to relatively lower size accuracy, necessitating larger machining allowances and higher labor intensity. As a result, open die forging finds its primary application in single and low-volume production scenarios.

3. Furthermore, open die forging surpasses casting blanks by eliminating defects like shrinkage, gas holes, porosity, and more, leading to products with enhanced mechanical properties.

2. Another distinguishing feature is the manual control of shape and dimensions in open die forgings. This manual operation leads to relatively lower size accuracy, necessitating larger machining allowances and higher labor intensity. As a result, open die forging finds its primary application in single and low-volume production scenarios.

3. Furthermore, open die forging surpasses casting blanks by eliminating defects like shrinkage, gas holes, porosity, and more, leading to products with enhanced mechanical properties.

Main Equipments Involved

Equipment for open die forging primarily falls into two categories: forging hammers and hydraulic presses. The main types of forging hammers in use are air hammers and steam hammers. Hydraulic presses operate by utilizing static pressure generated by a liquid to deform blanks.

The Process of Open Die Forging

The fundamental open die forging process comprises operations such as upsetting, drawing out, punching, bending, torsion, mismatch, and cutting.

1. Drawing out, also called elongation, involves decreasing the cross-sectional area while increasing the length of the blank.

2. Upsetting is a forging process that reduces height while increasing cross-sectional area, often used for manufacturing gear blanks and rings.

3. Punching in forging involves pushing material through a hole or non-through hole in the billet.

4. Bending is performed using specific tools or molds to achieve the desired shape.

5. Cutting is the process of dividing the billet into sections or removing a small portion from one end.

6. Mismatch involves moving a part of the billet by a certain distance while maintaining parallel alignment between the two axes.

2. Upsetting is a forging process that reduces height while increasing cross-sectional area, often used for manufacturing gear blanks and rings.

3. Punching in forging involves pushing material through a hole or non-through hole in the billet.

4. Bending is performed using specific tools or molds to achieve the desired shape.

5. Cutting is the process of dividing the billet into sections or removing a small portion from one end.

6. Mismatch involves moving a part of the billet by a certain distance while maintaining parallel alignment between the two axes.

Advantages of Open Die Forging

Open die forging offers several advantages, including:

●Flexibility: The versatility of this method allows for the production of a diverse range of shapes and sizes, accommodating both small and large components.

●Improved Mechanical Properties: Controlled deformation and grain alignment during open die forging lead to improved mechanical properties, such as increased strength, toughness, and resistance to fatigue.

●Cost-Effective: Open die forging is often a cost-effective choice for custom or low-volume production, as it typically requires less investment in tooling and equipment compared to closed die forging.

●Customization: Manufacturers can readily tailor products to meet precise design requirements, including one-of-a-kind or prototype components.

●Improved Mechanical Properties: Controlled deformation and grain alignment during open die forging lead to improved mechanical properties, such as increased strength, toughness, and resistance to fatigue.

●Cost-Effective: Open die forging is often a cost-effective choice for custom or low-volume production, as it typically requires less investment in tooling and equipment compared to closed die forging.

●Customization: Manufacturers can readily tailor products to meet precise design requirements, including one-of-a-kind or prototype components.

The Open Die Forging Applications

Open die forging necessitates subsequent rough machining owing to its free-forging nature, and precise dimensions can be achieved through secondary precision machining. This forging technique is particularly well-suited for manufacturing large components, often weighing several tons. Typical products produced using this method include forged long shafts, rollers, cylinders, and more, which find applications in railway systems, aerospace, and various other industries.

Open die forging stands as a versatile and well-established technique for shaping metals into diverse components. Its flexibility, cost-efficiency, and capacity to enhance material properties render it a valuable process across various industrial sectors.

Open die forging stands as a versatile and well-established technique for shaping metals into diverse components. Its flexibility, cost-efficiency, and capacity to enhance material properties render it a valuable process across various industrial sectors.